Automotive

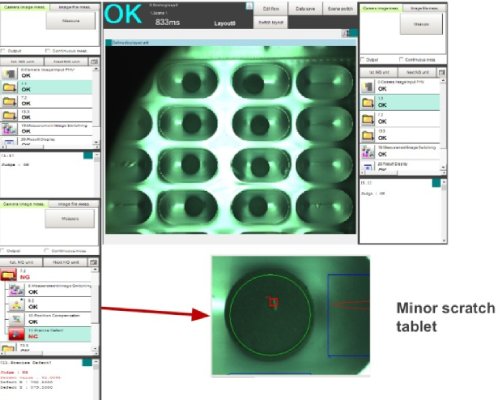

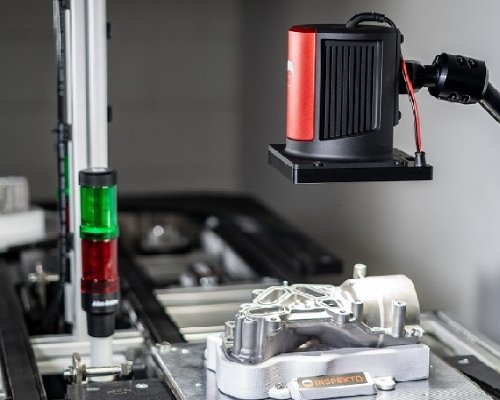

- Surface defects - Dents, damages, scratches, cracks, rust/color Variation

- Assembly Inspection- Child Part Missing

- Casting parts - DPM Reading & Character Verification (OCR)

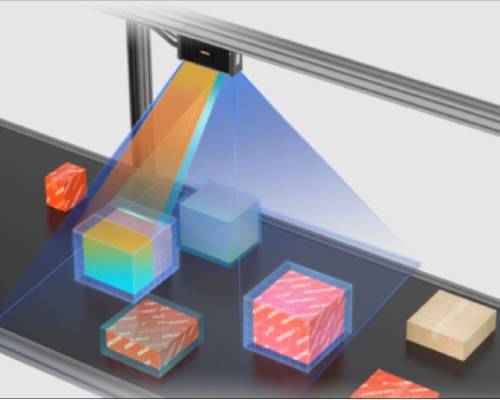

- Machine parts - Counting in packages

- Print quality - Colour, offsets, misprints, smudges.

- All Component - Dimension Measurement (10-20µm)