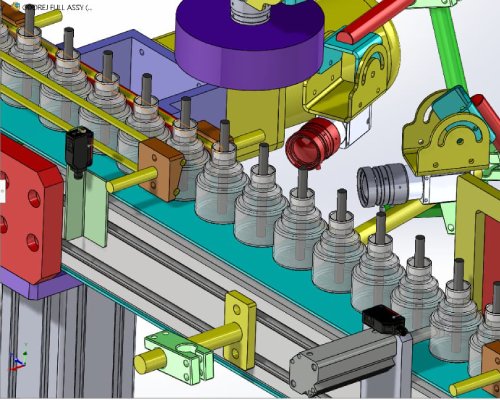

FMCG Industrial Application

Quality inspection is a vital aspect in the FMCG industry that ensures customers receive high-quality products. The process involves assessing the goods for any defects or flaws that could affect their usefulness. Quality inspectors use various tools and techniques such as visual inspection, sensory evaluation, and laboratory testing to identify any issues. It is essential that the inspection is carried out throughout the production process, from the raw materials to the finished products. FMCG companies invest heavily in quality inspection to uphold their brand reputation and ensure customer satisfaction. With stringent regulations and competition, quality inspection is crucial to operations and success in the FMCG industry.